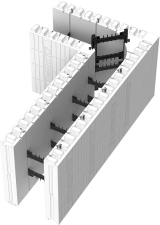

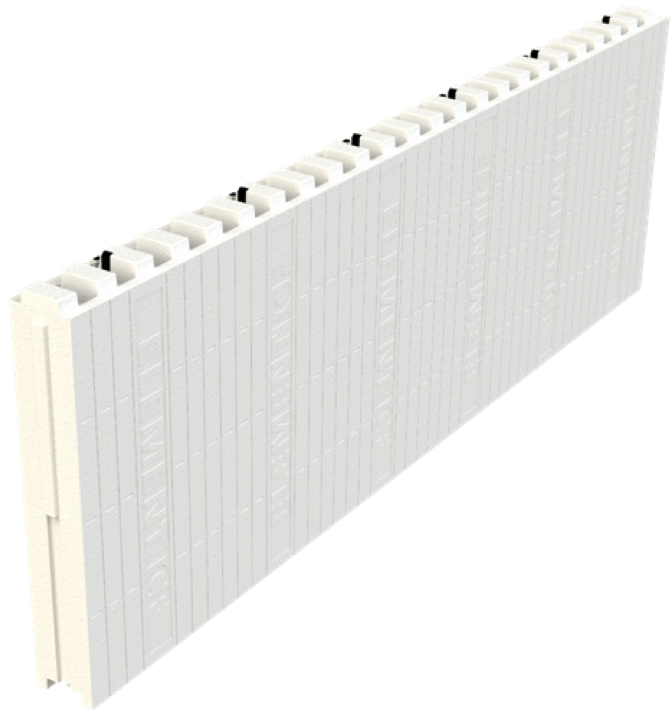

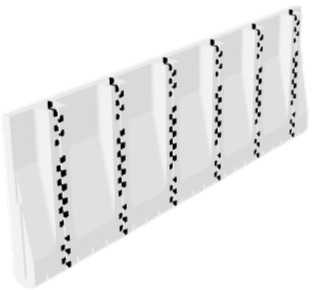

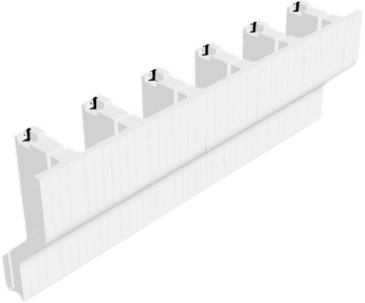

You are starting your construction project on the right foot when you choose to work with Insulated Concrete Form (ICF) blocks.

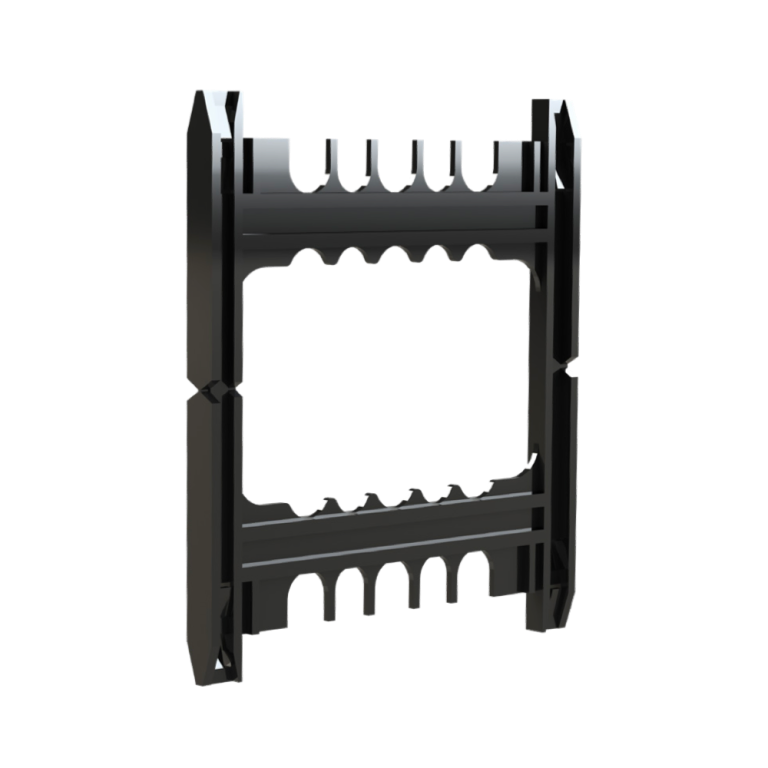

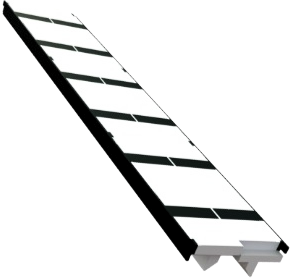

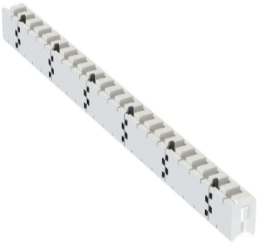

You can improve the reliability of your structure when you build with Element ICF by Logix, one of the most trusted and versatile product lines in the industry. Solid ICF has a complete selection of Element ICF blocks in stock in our warehouse. We can also offer expert knowledge on this product to help you succeed in your construction project.